Cooling Fan Technology by SANYO DENKI AMERICA

Providing Cooling Solution with High Performance and Reliability

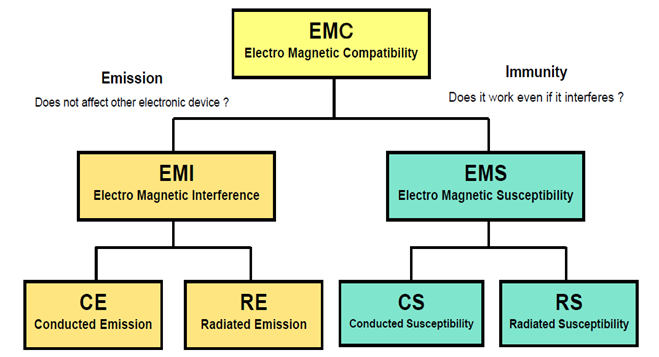

In today’s high demand for technological advancements, Electro-Magnetic Compatibility (EMC) plays a pivotal role. As designs become more powerful, efficient, and low-profile, they also become highly dense, necessitating a keen awareness of EMC considerations.

EMC can be broken down into two critical aspects:

Electro Magnetic Interference (EMI): This refers to the ability of electronic devices not to interfere with other nearby electronics. Imagine annoying lines on your television screen or instrument malfunctions during a commercial flight—these are classic examples of EMI-related issues.

Electro Magnetic Susceptibility (EMS): On the flip side, EMS pertains to a device’s ability to remain unaffected by other electronics in its vicinity. For instance, pilots strongly advise against using large electronic devices during take-off and landing to avoid potential interference.

The impact of EMC extends across various domains:

Residential: Think of the frustrating interference on your home entertainment systems due to neighboring electronic devices.

Medical: In healthcare settings, sensitive medical equipment must function flawlessly without being disrupted by nearby electronics.

Aeronautical: Commercial airplanes rely on precise electronic systems, and any EMC-related glitches could compromise safety.

Even cooling fans are not immune to EMC challenges. Here’s why it matters:

EMS and Corrosion: EMS can lead to electric corrosion in fan bearings which reduces the lifespan of the fan and increases physical noise and current. Strong discharges of electromagnetic noise are created by high power and frequency devices. These discharges penetrate through the bearing grease and allow current to pass through the bearing ball. As the ball rotates within the bearing during these discharges of noise, undulating wear appears on the rotating surface of the ball. In this abnormal state of the ball, the bearing will make unwanted audible noise and vibration in operation.

At SANYO DENKI, we understand the critical importance of EMC. Our expertise lies in providing effective solutions to tackle EMC-related issues. Here are some features we offer:

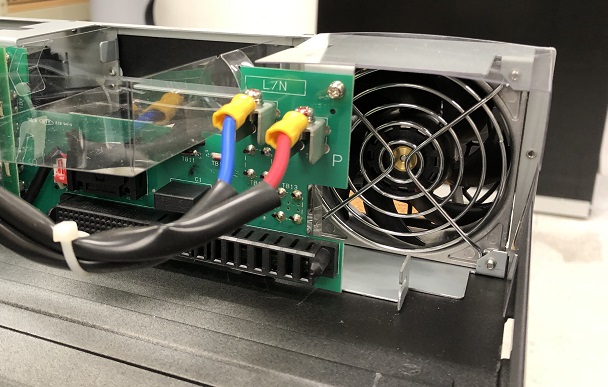

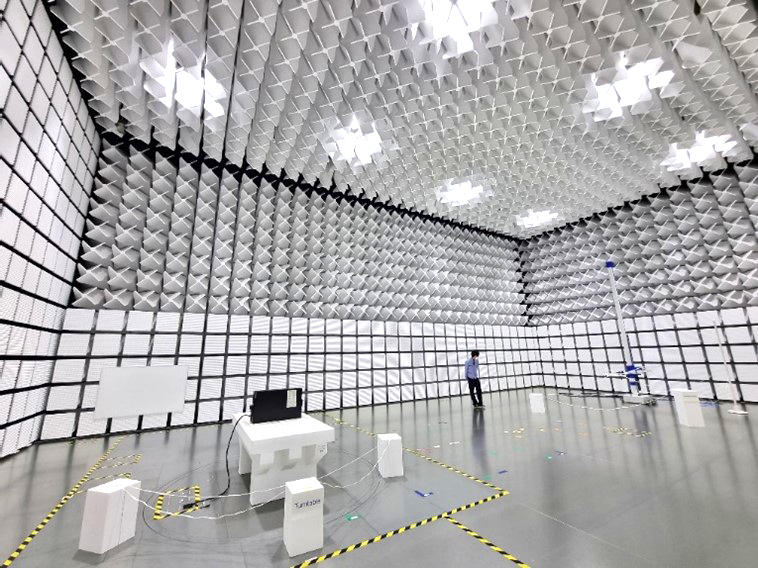

SANYO DENKI recently established a state-of-the-art EMC test lab at our facility in Japan. This facility allows us to rigorously test custom circuitry for any application, ensuring top-notch performance and compliance with EMC standards.

When it comes to EMC, trust SANYO DENKI to keep your systems running smoothly, interference-free, and optimized for the demands of today’s technology-driven world. For assistance with troubleshooting your fan EMC issues, reach out to your local SANYO DENKI representative for in-depth guidance.

For more information, visit our website or contact us.

Written by Mohammed Nassan

SANYO DENKI has been a trusted provider of cooling solutions for various industries, with fans being a crucial component in many advanced devices. Contact us for a quote, or to discuss your device's customization requirements.

Our experienced application engineers and field engineers will provide support on the customization or any other technical support for your equipment. Contact our representatives or distributors to start discussing your next project.

Contact Us