Cooling Fan Technology by SANYO DENKI AMERICA

Providing Cooling Solution with High Performance and Reliability

Selecting the right fan is crucial to meeting your thermal goals. Besides choosing the fan based on basic requirements like CFM, static pressure, power and noise, there are also bearing types to consider. This brief article will explain the pros and cons to help you select which bearing type is best suited for your application.

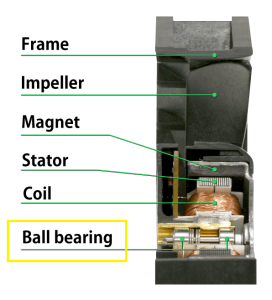

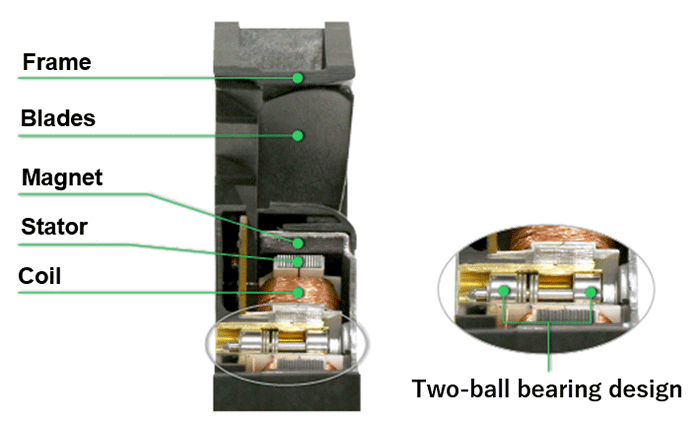

Bearing types can be broken down into two groups, ball bearings and sleeve bearings. Both bearings have an inner and outer race to mount the rotor shaft to the fan frame and have grease in-between to reduce heat, friction, and degradation. However, ball bearings use steel (or ceramic) balls to help distribute the load while sleeve bearings rely only on grease as the primary interface.

To determine which type is best suited for your application, the design engineer must decide on the following:

Let’s examine each question:

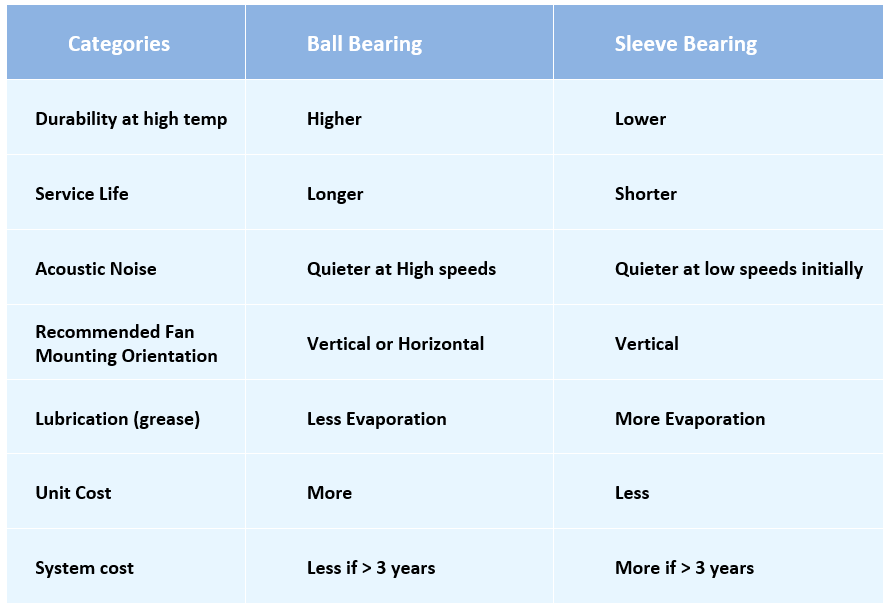

The table below summarizes these characteristics of ball bearing and sleeve bearing*:

*Data compiled from several ball bearing supplies

In summary, as a rule:

Rest assured; all SANYO DENKI fans use only dual ball bearings to ensure a long service life at higher operating temperatures resulting in a lower system cost.

Please feel free to contact your local SANYO DENKI AMERICA sales office or sales representatives with any questions and we will be glad to help you.

Written by Gary Masessa

SANYO DENKI has been a trusted provider of cooling solutions for various industries, with fans being a crucial component in many advanced devices. Contact us for a quote, or to discuss your device's customization requirements.

Our experienced application engineers and field engineers will provide support on the customization or any other technical support for your equipment. Contact our representatives or distributors to start discussing your next project.

Contact Us

[…] Learn more on different types of bearings: Which is Right For You? Ball Bearings vs. Sleeve Bearings […]