Cooling Fan Technology by SANYO DENKI AMERICA

Providing Cooling Solution with High Performance and Reliability

DC fans with a four-wire configuration consist of power, ground, tach pulse output, and PWM input control for varying speed. Being able to vary the speed of the fan basically optimizes the cooling fan’s performance for your specific application needs.

DC fans with a four-wire configuration consist of power, ground, tach pulse output, and PWM input control for varying speed. Being able to vary the speed of the fan basically optimizes the cooling fan’s performance for your specific application needs.

Originally, when the PWM input control was lowered to zero percent duty cycle, the fan would idle at a low speed, for example, a few hundred RPMs. But over the last several years, a feature we call “Zero Stop” (ZS) was added at the request of customers to many of our newer fan models which allows the impeller to stop rotating.

So why would you want a fan with the ZS feature?

Two ways:

1) From the catalog sheet, as denoted by the *:

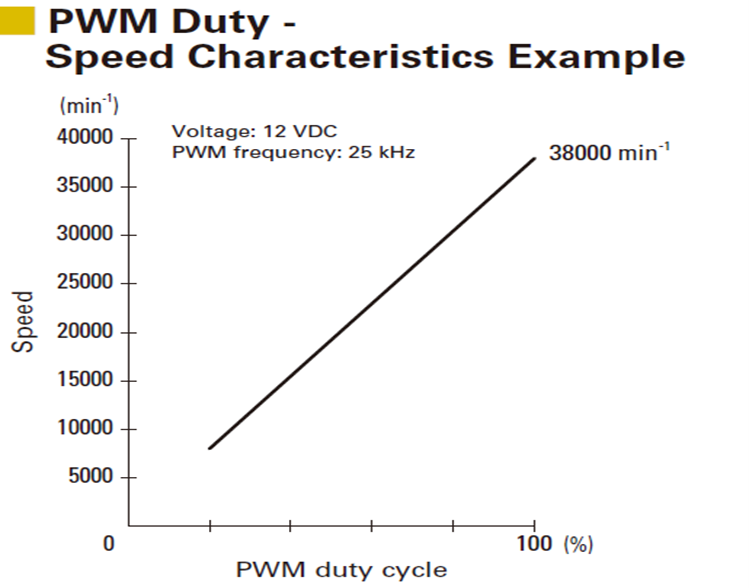

We see in the above spec table, this fan draws 1.4W when the PWM duty cycle is 20% and provides 7.8 CFM, 0.41 in H2O which for this model is essentially idling… But this fan has the ZS feature (as denoted by the *) so when the PWM duty cycle drops below 20% and as it approaches 0% the fan will stop rotating and draw little to no power. The reason for the lack of exactness of the duty cycle percentage for when the fan will stop is due to the tolerances of the windings, discrete components, and lot to lot manufacturing variations, so it is best to stay above the 20% level if you want the fan to rotate. This lack of exactness is shown in the speed vs duty cycle graph shown below, note:

2) From Datasheet:

If you request the datasheet for the specific fan model, you can see the 0% PWM duty cycle reduces power draw from 1.4W (12VDC x 0.12A) to 0.48W (12VDC x 0.04A) max.

In closing, the benefits of the ZS feature found in many of our DC fans are power savings, reduced noise and extending the service life of the fan.

Written by Gary Masessa

Our experienced application engineers and field engineers will provide support on sensor customization or any other technical support for your equipment.

[…] See other useful articles in this blog on the benefit of the pulse sensor on a DC fan or on the zero stop feature in a DC Fan. […]

[…] Learn about Zero Stop Feature: WHAT IS THE ZERO STOP FEATURE IN A DC FAN? […]