Cooling Fan Technology by SANYO DENKI AMERICA

Providing Cooling Solution with High Performance and Reliability

A commercial kitchen equipment manufacturer recently started developing a new commercial induction heating (IH) cooker model but faced several technical challenges.

For the new model under development, it was essential to make it significantly smaller than the existing model. An axial fan was installed to discharge the heat inside the IH cooker, but to make it smaller, The height of the fan was an issue.

Therefore, in order to reduce the height of the new model, the size of the axial fan was reduced but it turned out that sufficient cooling performance could not be obtained.

Commercial IH cookers must efficiently cool the heat generated by the magnetic field generating coil. Product failures hinder the operation of customers’ stores and directly lead to a decrease in sales. To successfully develop the new model, it was necessary to find a fan with sufficient performance.

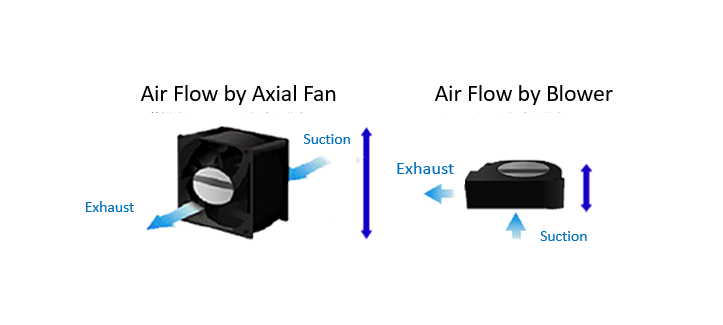

SANYO DENKI suggested replacing it with a blower, so the size of the entire device can be significantly reduced. Unlike axial fans, the blower draws in air from the side of the fan because the suction and exhaust are at right angles. Therefore, the height of the device can be reduced by installing the blower on its side.

With a blower, the heat source can be cooled directly and efficiently because it can send air with high static pressure and in a straight direction. In conventional axial fans, the wind was dispersed in many cases and it was necessary to create a duct to guide the wind. By installing a blower fan, the customer not only saved space but also reduced design man-hours and material costs.

Furthermore, the expected life of Sanyo Denki’s blowers is 40,000 hours (*), so we expected that there would be no problems with durability.

The PWM control function can be expected to save energy by appropriately controlling the rotation speed.

* L10: Residual rate 90% 60°C, rated voltage, continuous operation, at free air condition

See other useful articles in this blog on the benefit of the pulse sensor on a DC fan or on the zero stop feature in a DC Fan.