Cooling Fan Technology by SANYO DENKI AMERICA

This site is part of SANYO DENKI’s official cooling engineering knowledge base.

In the DC fan world, fans come in two, three, and four wire configurations as follows:

In the DC fan world, fans come in two, three, and four wire configurations as follows:

Two wire – Just power and ground, fans run at full speed, no speed control or pulse sensor (AKA Tach) output.

Three wire – Power, ground and pulse sensor output to monitor RPMs. No speed control.

Four wire – Power, ground, pulse sensor output and PWM input control for varying speed.

Originally, the third wire was added to provide what is called a “lock rotor” feature, which provides a logic high level if the impellor stopped rotating to alert your system to shut down and prevent overheating. However, years later when fans were introduced with speed control (via PWM lead wire), the third lead wire was offered as a pulse sensor output so the RPMs could be monitored when the PWM duty cycle was changed.

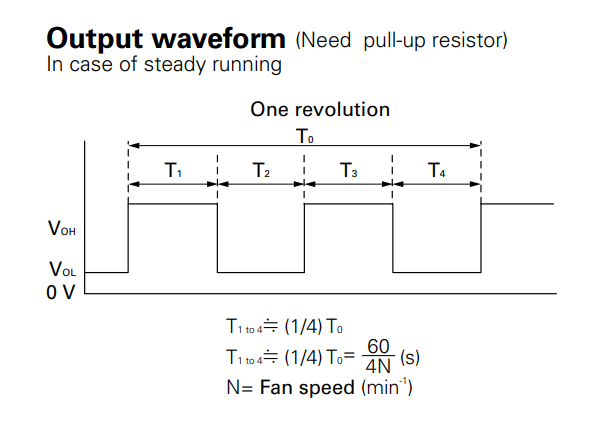

Note two pulses per revolution for the pulse sensor output is the most common industry practice.

This would also still provide an alert like the “lock rotor” feature since if the impellor stopped rotating, the output pulses would stop at either a logic high or logic low. Note while the lock rotor feature is still available today, the pulse sensor output has become much more popular and common.

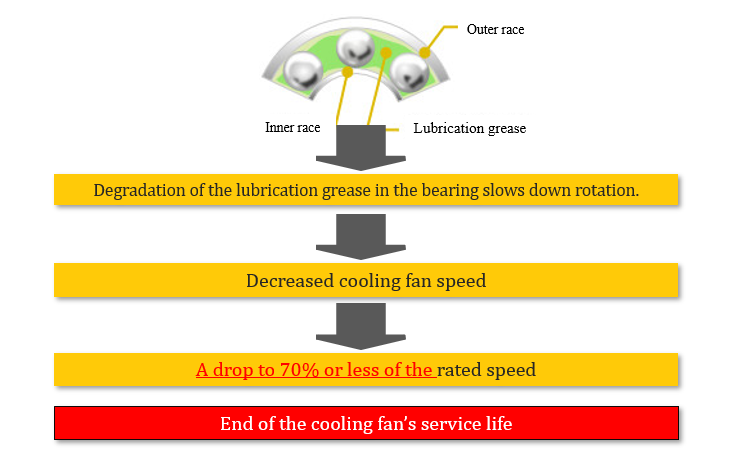

A benefit overlooked of the pulse sensor output is that it can indicate the health or the service life of the fan so you can plan for maintenance. Let me explain, we at Sanyo Denki view a fan coming to an end of its service life when its RPMs drop to 70% of the nominal value.

For example, a fan which has a nominal RPM spec of 10,000 at full speed, shows the speed declining as time goes on over years of continuous use. Once it approaches 7,000 RPMs, the customer’s monitoring firmware can send a flag signal to indicate that the fan will need to be replaced. This comes in very handy when other planned system maintenance is needed such as in remote locations where doing maintenance is not available year-round based on accessibility or having your system shut down without warning.

Note that this feature works for both open loop fans (which don’t have feedback) and for closed loop fans.

Let me explain for closed loop fans (fans that have feedback so the speed remains constant when the load changes) the fan’s current draw will slowly increase to account for the additional load from the grease degrading but when it reaches the internal current limit, the rotation speed will start to decrease so this can still be used to monitor for the heath/service life of the fan.

So why would you not want a pulse sensor output?

In closing, the benefit of using a three-wire fan with pulse sensor output is to monitor the health of the fan to determine when the fan service life is approaching replacement and to schedule maintenance.

Written by Gary Masessa

[…] An Overlooked But Useful Benefit Of The Pulse Sensor On A DC Fan […]

[…] other useful articles in this blog on the benefit of the pulse sensor on a DC fan or on the zero stop feature in a DC […]

[…] An Overlooked But Useful Benefit Of The Pulse Sensor On A DC Fan […]

Thank you for your description of Three-wire: Power, ground, and add a tach pulse/lock sensor output to monitor RPMs.

An Overlooked But Useful Benefit Of The Pulse Sensor On A DC Fan

I have a question about replacing a fan in one of my 3 identical Video Projectors.

My MITSUBISHI LVP-SA51U Video Projector includes an exhaust fan labeled

Model 3108NL 04W B29

12VDC 0.14A

DC BRUSHLESS,+RED,-BLACK

MINE BE A COL TD

Three wires are Black, Red, White.

I replaced that fan that no longer would rotate, stuck, with a similar size fan labeled

12 VDC 0.14A with only two wires, red and black.

The fan rotates, moves air, but Video Projector status indicates over heated or fan condition not acceptable.

Next I borrowed a functional fan from one of the other functional projectors, replaced 2-wire fan with borrowed 3-wire fan, tried starting projector. Projector starts normally. Original fan makes big difference. Next test was to power-on projector with fan blade rotation inhibited. That inhibited projector from starting normally. Try projector again after power-off and remove blade rotation interference, this condition allows projector start-up normally and fully functional.

I have two choices:

1 – purchase replacement for obsolete fan. If you would sell me 1 compatible fan, please quote price including sales tax delivered to my residence in Salt Lake City, Utah, zip 84103.

2 – provide a substitute signal or voltage level on white wire to “fool” projector into recognizing an always on and blowing fast fan. If this option is used, then I need clear instruction on signal I must present to 3rd (white) wire. I am a retired Electronics Engineer who is willing to make a substitute, if practical.

Harvey Wilson

241 N Vine St. Apt 901W

Salt Lake City, UT 84103-1961

801-688-3385

harleewilson@hotmail.com