Cooling Fan Technology by SANYO DENKI AMERICA

Providing Cooling Solution with High Performance and Reliability

In this brief article we will give an overview of the features of our PWM Controllers that allow you to vary the speed of our 4 wire DC fans efficiently and conveniently.

Controlling the rotational speed of the fan (RPMs) has several advantages such as reduced system power consumption, minimized acoustic noise and so optimizes your design to meet your specific thermal needs.

For those not familiar with PWM Speed Control, please refer to our article How to Use PWM Speed Control to Improve Efficiency of Cooling Fans for an introduction.

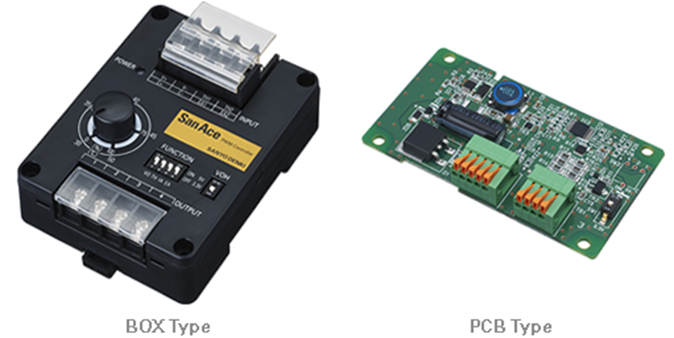

Our PWM Controllers come in two styles, the Box and the PCB type (see below). Each version provides unique control options, allowing users to choose the best fit for their applications.

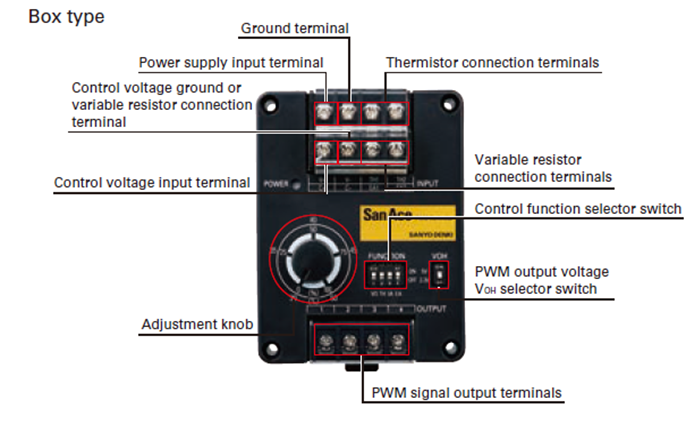

The main difference is the Box type can vary the RPMs four different ways based on the Control function DIP switch settings (see below) while the PCB versions have one set control method as noted by part number. The Box type provides versatility in control options, while the PCB version simplifies control with preset functionality.

The most common PWM frequency in the DC fan industry is 25KHz but we do offer a variant of 1KHz that is required for some models.

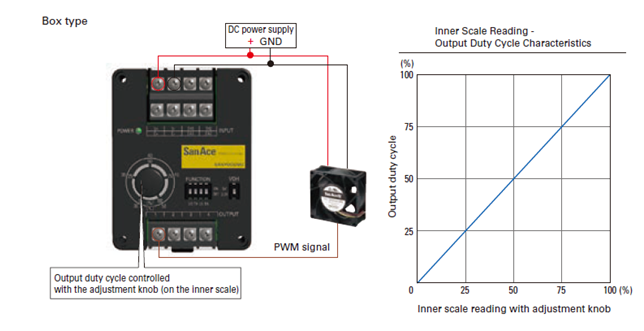

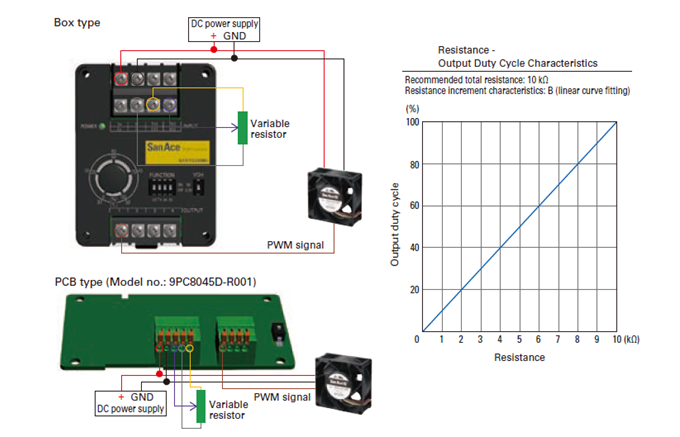

The Box type can vary the RPMs by four control methods (by internal adjustment, external adjustment, voltage control or thermistor control) as shown in the following diagrams:

Output duty-cycle controlled with the adjustment knob.

Output duty cycle controlled with variable resistor connected to terminals.

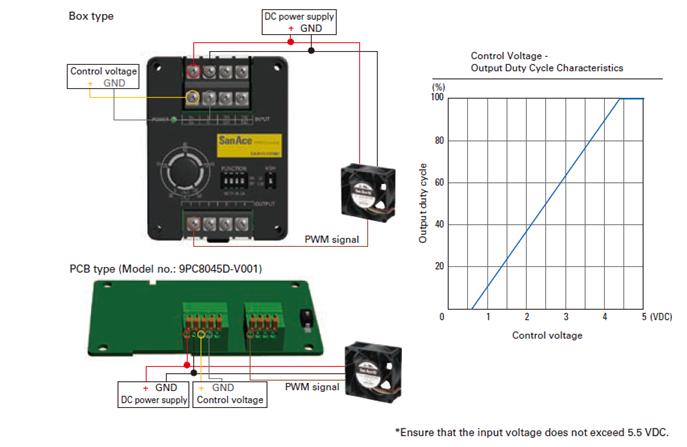

Output duty cycle controlled with input voltage of 0 to 5 VDC.

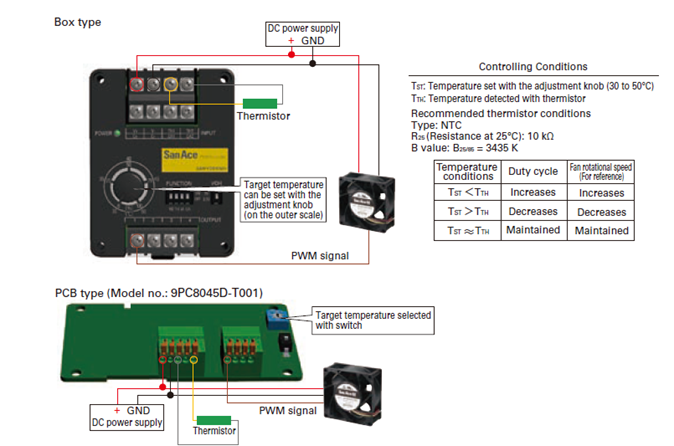

Automatic control of output duty cycle in response to the temperature detected with an external thermistor.

These varied control methods make the Box type PWM Controllers ideal for diverse applications requiring precise thermal management.

Both Box and PCB types can control the speed of up to four fans simultaneously providing the same PWM duty cycle signal. Additionally, they can be conveniently powered by the supply voltage of the fan 12, 24 or 48VDC.

For more technical details, download the instructional manual.

In closing, if you don’t have the capability or time to generate your own PWM signal, our PWM Controller is very easy to use and can get your thermal analysis going for your system very quickly.

Feel free to contact your local SANYO DENKI sales representatives or sales office with any questions about integrating the PWM Controller into your design.

Written by Gary Masessa

SANYO DENKI has been a trusted provider of cooling solutions for various industries, with fans being a crucial component in many advanced devices. Contact us for a quote, or to discuss your device's customization requirements.

Our experienced application engineers and field engineers will provide support on the customization or any other technical support for your equipment. Contact our representatives or distributors to start discussing your next project.

Contact Us