Cooling Fan Technology by SANYO DENKI AMERICA

This site is part of SANYO DENKI’s official cooling engineering knowledge base.

Our DC fans are used in numerous applications worldwide and occasionally are subjected to unexpected, poor air quality (pollution) environments not anticipated by the original system designer that over time can cause the fans to fail.

In this brief article, we will explain the problem and offer the easiest solution to correct and extend the service life of your DC fans in a harsh environment.

Before we begin, keep in mind we have an extensive product offering of DC fans for harsh environmental applications like our wide temp, IP rated or long-life fan series. This article discusses when the customer uses our standard series fans that are installed in application specific harsh environments. Recently we have seen two different customers with fan failures attributed to damage from poor air quality. Both instances used high-performance counter rotating series fans which are mostly used in telecom, server and data storage end applications and are commonly installed in air quality-controlled environments.

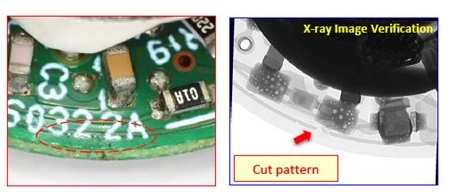

This design has been in production for ~ 13 years, with no field returns until the customer started to install systems in an Asian country. Within a few years, they started to get failures and alerted us of the issue. After doing a complete failure analysis, the root cause was determined to be corrosion from pollution and high humidity. As you can see in the pictures below, corrosion damage occurred where the lead-wires are soldered to the PCB and in this case, eventually disconnected the red power lead wire.

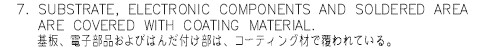

This design has been in production for ~ 10 years, with no field returns until the customer began installing systems in a southeast Asia country. Within a few years, fans started to fail and again it was determined that corrosion was caused by pollution and high humidity. As you can see in the Figure below, the PCB trace was corroded and became open.

The accumulated dust found on the returned fans was chemically analyzed and the results showed 48% Chlorine (Cl), 25% Potassium (K) and 21% Calcium (Ca). These elements, when combined with high humidity, lead to the corrosion of the metal traces on PCBs, causing permanent electrical failure.

Adding a conformal coating to the PCB such as Pelgan Z, a silicone-based product, would provide a layer of protection against such chemicals mentioned above and resist corrosion. Conformal coating is a simple customized addition that can be added to any of our standard fan series and does not change the performance of the fan so the customer would not have to do a thermal requalification.

Documentation traceability would be done by revising our drawing, adding a comment to the notes section and cutting in the change to a specific lot/date code.

In closing, high concentrations of air pollution combined with high humidity can cause an increased chance of fan failures as well as other component failures within your system. While we do not require our standard fans be operated in a “clean room” environment, some minimal steps should be taken to ensure the fans are protected from these situations.

However, if your design team didn’t consider this for a specific harsh environment location, we can solve your issue by adding conformal coating (such as Pelgan Z) to the PCB of the fan to increase corrosion protection and extend DC fan life. Please contact your local SANYO DENKI AMERICA representative to learn more.

Written by Gary Masessa

For more technical information about DC fans, you might be interested in learning How to Identify 2, 3, 4 Wire DC Fans: A Model Number Guide. https://coolingfans.blog/how-to-identify-2-3-4-wire-dc-fans-a-model-number-guide/)

This article is part of SANYO DENKI AMERICA’s San Ace cooling engineering knowledge base, sharing practical guidance engineers use when working with DC fans in electronic cooling designs.

SANYO DENKI has been a trusted provider of cooling solutions for various industries, with fans being a crucial component in many advanced devices. Contact us for a quote, or to discuss your device's customization requirements.

Our experienced application engineers and field engineers will provide support on the customization or any other technical support for your equipment. Contact our representatives or distributors to start discussing your next project.

Contact Us