Cooling Fan Technology by SANYO DENKI AMERICA

This site is part of SANYO DENKI’s official cooling engineering knowledge base.

Managing the impact of environmental conditions on a thermal management system is often difficult when designing a system for use in harsh environments. Typically, electronic devices such as fans do not fare well in conditions such as water, dust, oil, or high and low temperatures.

The best way to protect a system from premature failure is to design a thermal management system which is robust enough for the environment in which it will operate. Sanyo Denki facilitates this by supplying customers with a wide variety of environmentally protected fans to suit unique design needs.

Some fan options which we offer are:

Each of these different fan series are designed for optimal use in different systems. Let us look at what makes each of these fan styles different and how they can be best utilize in a system.

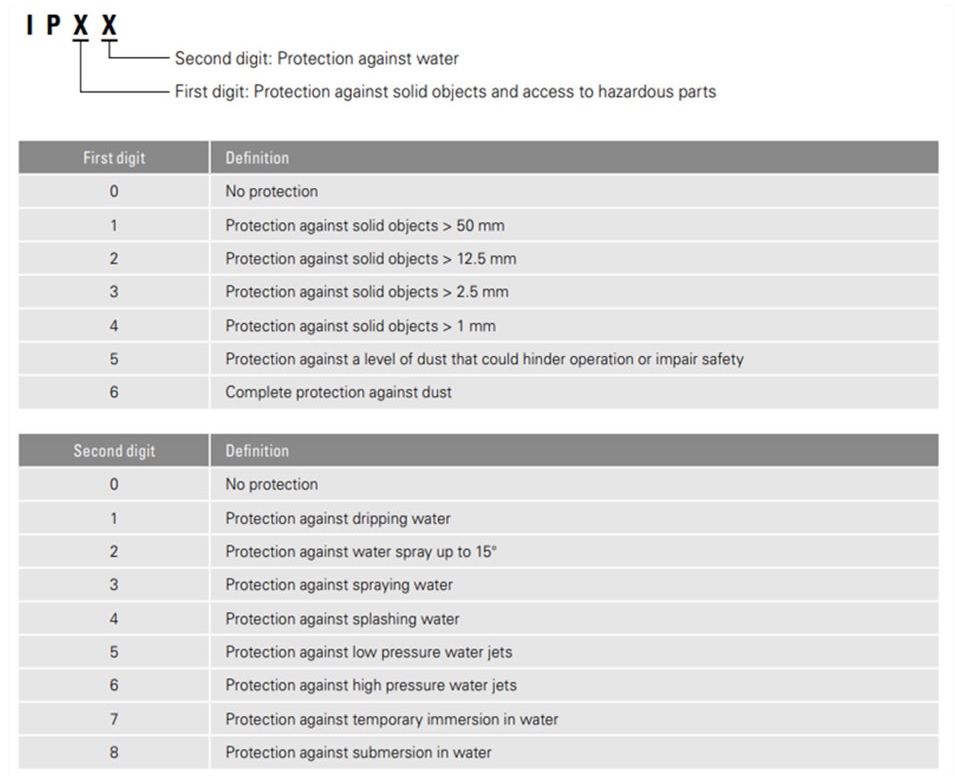

As mentioned, these fans are useful in outdoor environments because they can withstand sustained or transient presence of water and dust. For the best protection, these fans are designed to meet the IP68 ingress protection rating. This rating states that the Sanyo Denki Splash Proof fans are designed for full protection from any size dust particle and full protection from full submersion in water.

This allows these fans to be mounted into a system without any extra shielding or venting to protect your fan during harsh weather.

The long-term benefit can be reduced system cost, reduced maintenance, and higher quality for a system. On top of these benefits, Sanyo Denki offers a large variety of varied sizes which are IP68 rated. This includes axial fans between the sizes of 40mm to 172mm frames as well as offerings in the Centrifugal, ACDC, and Blower frames.

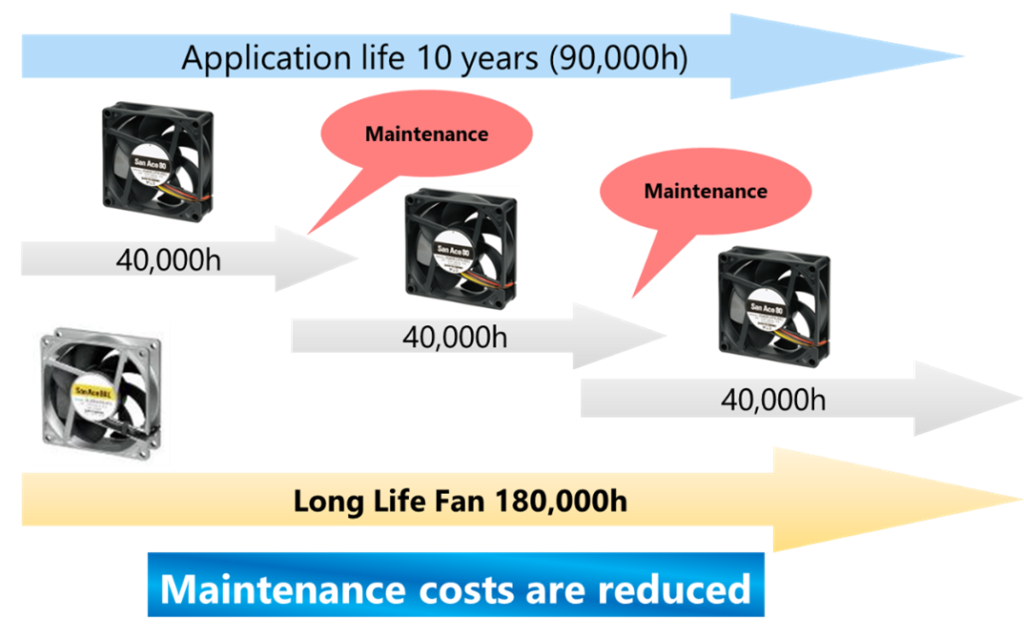

Long life fans are a specialty design used in applications

that want to increase the sustained usage of a fan without the need for

replacement. This is great for long operation applications (such as servers or

medical devices) or any device which may not have easy access to maintenance

(such as telecom base stations or 5G antennae). The industry standard fan life

falls somewhere in the ballpark of 30k to 40k hours of continuous usage at 60°C,

or about 4-5 years. The Long-Life series fans have a low-end life at 100k hours

at 60°C

with some models offering up to 200k hours at 60°C. on the high end, these fans

can last up to 23 years of continuous usage without a need for maintenance or

replacement. Overall, this means that your system can save money with

utilization of one long life fan instead of the effective usage of four

standard life fans.

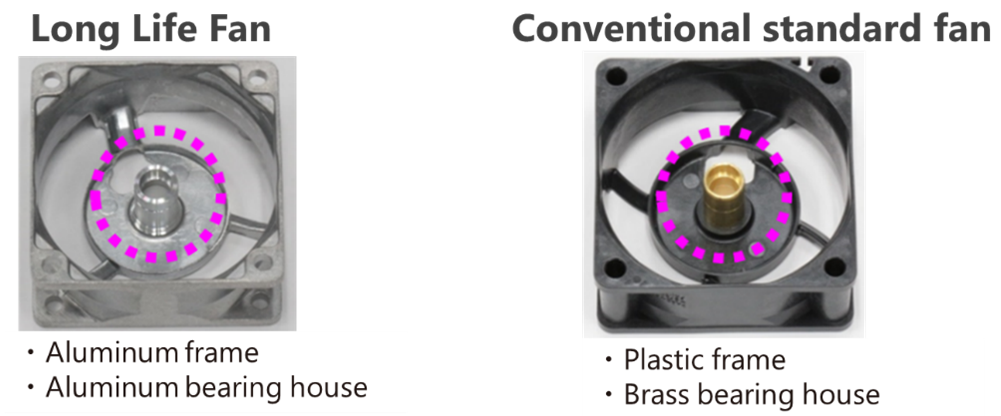

So how do we extend the life of these fans so drastically? The key to these designs is heat dissipation from the bearings and motor. The biggest cause of fan degradation over time is the excessive heat within the bearings of the fan. The Long-Life series fans addressed the heat built up internally by converting the entire fan frame into its own heat sink. By switching from a plastic frame to an aluminum frame, the heat can be dispersed away from the internal bearings and subsequently convection cooled away from the frame.

With an aluminum frame, the internal temperature rise of bearings can be reduced, resulting in the extension of fan life.

Long life fans also utilize special bearings and structural design which help to increase the overall durability of the design and allow it to operate for an extended life.

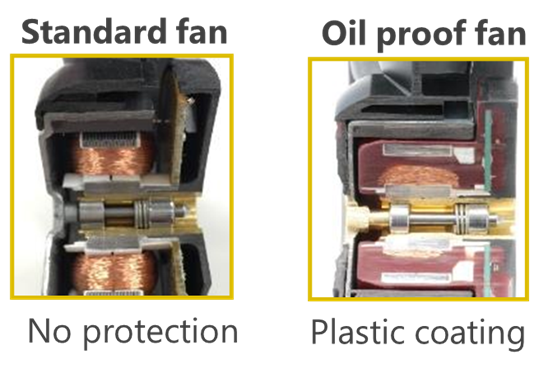

The oil proof series fans are viewed as the sister product

to the IP68 rated splash proof fans. Both fan families are aimed at preventing

ingress of foreign materials into the fan, however, the added strain caused by

oil ingress requires a distinct set of design features. Just like the Splash

proof fans, the Oil proof fans often utilize an epoxy coated electronics to

prevent any damage to the internal components.

Yet oil ingress into the electronics is not the only protection required. Many oils used in machining or food processing are often reactive to many types of plastics which causes fatigue or eventual failure of the plastic frames. Standard materials may degrade or soften over time, so Oil proof fans use specialty plastic materials which are designed to be inert with most common oil products.

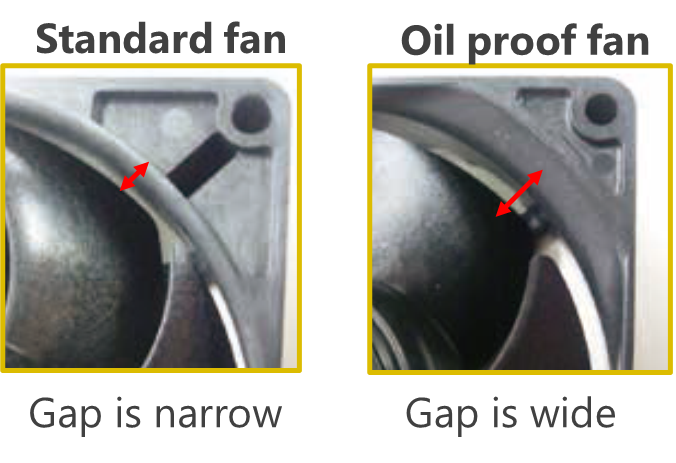

Another design aspect with oil proof fans is the consideration for oil build-up on the impeller blades. These fans increase the gap between the rotating impeller and the fan frame, and prevents oil debris buildup which over time would clog up and stop the fan.

These specialty fans are commonly used in applications where temperature fluctuations may occur. Wide temperature range fans leverage many of the same design practices seen in Long Life fans. However, they utilize their own unique benefits to allow for wider temperature ranges. Like the Long-Life fans, Wide Temp fans have a fully aluminum frame design to dissipate heat from the bearings. Yet instead of utilizing this extra heat dissipation for longer life, we can use this to allow for a wider temperature range. While these fans share similar frame designs, the Wide temperature fans also use specialty bearing grease and specialty electronics which are targeted for usage in extreme temperatures.

With these added developments, the fans can be used in temperatures as low as -40°C and as high as +85°C. This specification range allows for products for usage in a variety of outdoor applications (i.e., EV chargers, digital signage, military devices, etc.) where they may be located globally, no matter how hot or cold the local conditions.

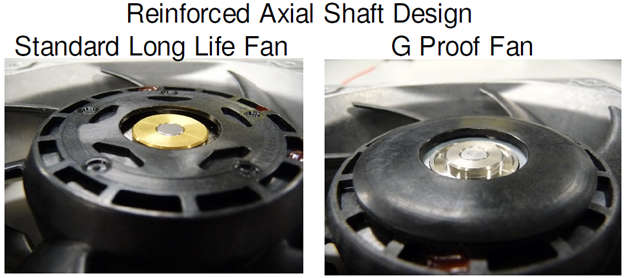

Easily the most rugged design in our catalog, the G-Proof series fans can take a serious beating in the harshest of operations. Originally designed for usage in CT scanner applications, these designs need to be able to withstand sustained G-forces up to 75G. This is accomplished by significantly increasing the size and durability of all structures in the fan, specifically the shaft and bearings.

By using oversized bearings and shaft, the fan structure can withstand significant external forces placed on the fan and frame without fear of damage.

This more robust design allows for these fans to be suited for any applications where high shock and vibration may be a concern. On-Vehicle and large machinery applications are typical places where these fans excel.

With the wide variety of environmentally protected fans offered, a system designer has the flexibility to push their device to the environmental limits without having to make sacrifices for accommodation of a standard fan. Also, we have seen that many of these options allow for cost savings in your long-term replacement and maintenance costs of a system. So next time you find a need to compromise due to environmental conditions, consider the Sanyo Denki’s options for environmentally protected fans since they may remove the need to compromise at all.

Written by Ryan Murphy

Check out other Engineering Blog Article here!

Our experienced application engineers and field engineers will provide support on sensor customization or any other technical support for your equipment.

[…] Learn more about IP (Ingress Protection) rating here […]

[…] from water and dust ingress to prevent internal damage. The 9WPA-Type fan achieves excellent IP68 water and dust protection, maintaining stable operation in harsh environments. With its compact size of 40mm frame size, it […]