Cooling Fan Technology by SANYO DENKI AMERICA

This site is part of SANYO DENKI’s official cooling engineering knowledge base.

When it comes to cooling solutions, not every fan is one-size-fits-all. Custom modifications, particularly to PWM control and sensor output, can drastically enhance performance and streamline system integration. At SANYO DENKI, our design center specializes in these electrical modifications to meet unique customer needs, providing tailored fans that improve efficiency and reduce complexity.

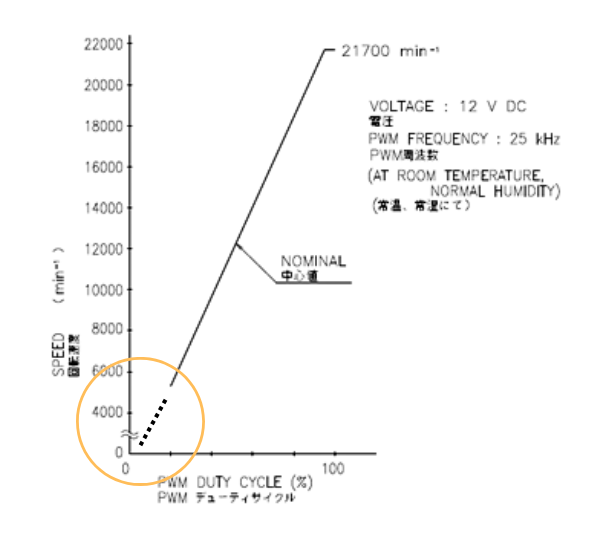

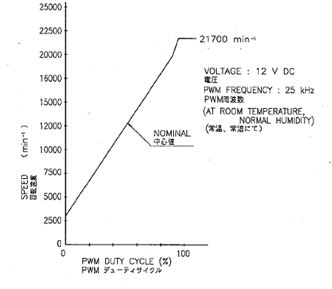

One of the most requested modifications is to the PWM control. By adjusting how the fan responds to PWM duty cycles, we offer more precise control over the fan’s performance.

Typically, a fan operates between 20%-100% PWM duty, with 0% PWM resulting in the fan being idle at 0 RPM. However, some applications require the fan to continue operating at a set RPM, even at 0% PWM. We can modify the fan’s PWM control to accommodate these requirements, allowing it to run at, for example, 3,000 RPM at 0% duty. This modification offers greater flexibility for applications where uninterrupted cooling is essential.

Figure 1: Guaranteed rotation at 20%-100% PWM duty, with 0 RPM at 0% PWM.

Modified to maintain 3,000 RPM at 0% PWM duty.

Figure 2: Below excerpt shows the customized fan with 0% PWM duty at 3,000 RPM

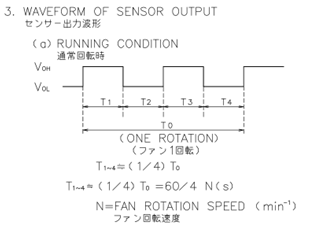

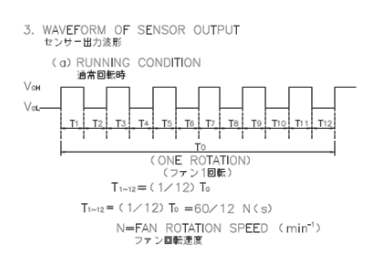

Modifying the sensor output is another critical customization we offer. Standard fans are typically designed to provide 2 pulses per revolution. However, certain applications may require more detailed feedback. In these cases, we can adjust the sensor output to provide 6 pulses per revolution, offering a higher level of precision in system integration.

By customizing the pulse rate, we help simplify the customer’s hardware and software development, allowing for seamless integration without the need for additional external components.

Figure 3: 2 pulses per revolution.

6 pulses per revolution for enhanced system monitoring.

Figure 4: Detailed view of customized fan with 6 pulses per revolution

A customer needed a fan without speed control, but our catalog only offered 4-wire fans with PWM control. Our solution?

➜ Removed the PWM wire to convert it into a 2-wire fan.

➜ Modified the sensor to provide 6 pulses per revolution for better feedback.

➜ Delivered a simplified yet high-performance cooling solution.

This optimization streamlined the customer’s design while maintaining performance and reliability.

At SANYO DENKI, we not only specialize in custom modifications but also prioritize 100% inspection of every fan we produce. Whether it’s a standard or custom fan, we ensure each unit meets the highest quality standards. For customers with additional inspection needs, we offer end-of-line inspection on fan assemblies, giving you complete confidence in the final product.

➜ Standard and custom fans alike are fully inspected before shipping.

➜ End-of-line inspections are available for fan assemblies, ensuring confidence in the final product.

Written by Morris Saypanya

SANYO DENKI has been a trusted provider of cooling solutions for various industries, with fans being a crucial component in many advanced devices. Contact us for a quote, or to discuss your device's customization requirements.

Our experienced application engineers and field engineers will provide support on the customization or any other technical support for your equipment. Contact our representatives or distributors to start discussing your next project.

Contact Us