Cooling Fan Technology by SANYO DENKI AMERICA

This site is part of SANYO DENKI’s official cooling engineering knowledge base.

A cooling fan finger guard must protect hands and block debris without hurting airflow or adding unwanted noise. Geometry, finish, and build quality determine whether your cooling system performs as planned.

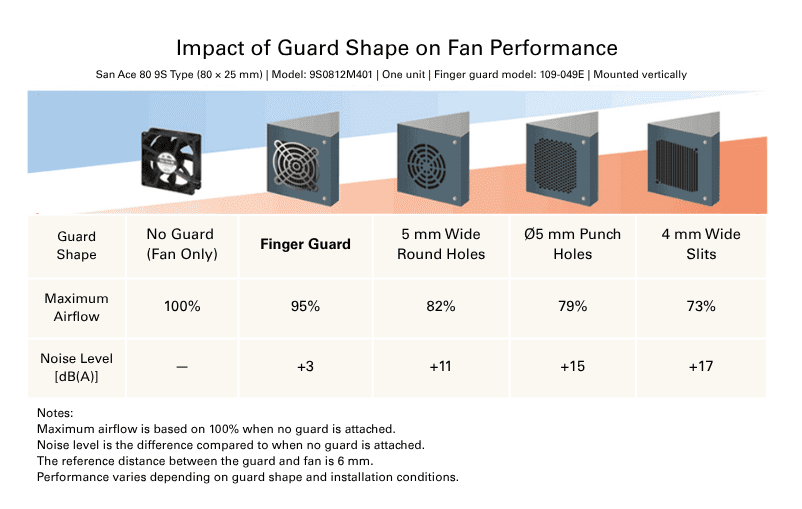

Smaller open area increases flow resistance. That shifts your system curve up, cutting maximum airflow and often adding noise at the same RPM. Wire guards generally preserve performance best because they maintain higher free area and present smoother edges to the airstream. Punched plates and narrow slits look tidy but throttle the inlet; if you choose them for styling or tamper resistance, expect trade-offs you’ll need to validate.

As open area drops, airflow decreases and noise increases; wire guards show the smallest penalty at equal fan speed.

| Guard type | Open area (qual.) | Airflow impact (same RPM) | Noise impact (same RPM) | Notes |

|---|---|---|---|---|

| Wire finger guard | High | Small loss | Small rise | Best balance for electronics cooling |

| Concentric punched plate (~5 mm) | Med–Low | Noticeable loss | Medium–High rise | If used, enlarge/space holes to regain free area |

| Round-hole plate (φ5 mm) | Medium | Moderate loss | Moderate rise | Chamfer/radius edges to reduce tonal noise |

| Narrow-slit plate (~4 mm) | Low | Highest loss | Highest rise | Use only when required; validate at the target duty |

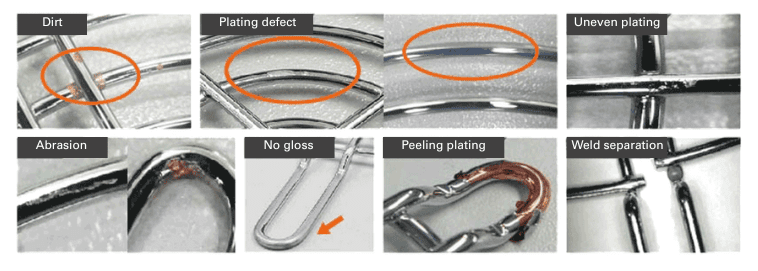

Finger guards prevent fingers and foreign objects from reaching the blades—but that safety function is compromised if welds peel or crack, allowing the guard to deform or detach. If plating flakes off, fragments can be pulled into the airflow and adhere to electronic circuits, risking shorts or corrosion-related malfunctions. Even scratches and grime on the guard degrade perceived quality and the product’s visual texture, which matters on customer-facing equipment. Build these into your acceptance criteria.

Examples of weld peel and plating flake risks; scratches and dirt affect product texture and perceived quality.

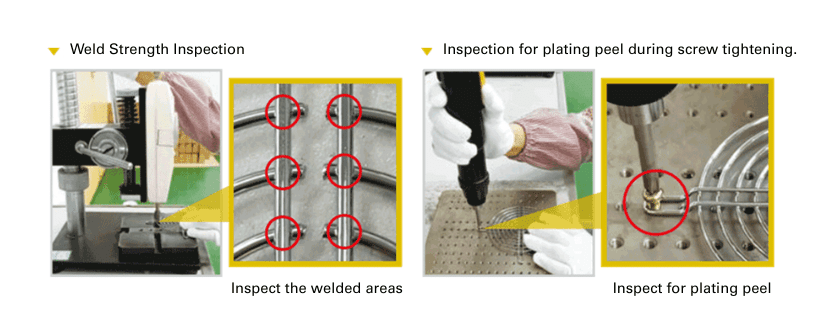

Examples of SANYO DENKI’s manufacturing process include weld checks, coating/appearance inspection, and fixture-controlled processes that drive consistent guard quality.

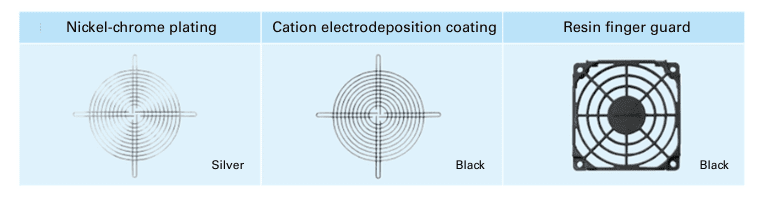

SANYO DENKI offers finger guards with cationic electrodeposition coating (high corrosion resistance) and resin types recommended for wet or corrosive environments—pair with SANYO DENKI waterproof fans for best durability. Nickel–chrome plated guards are also available but are not the top choice around moisture.

If your cooling fan finger guard will also hold a filter or sit in front of an EMI honeycomb, remember that each added layer increases airflow resistance. Plan for this early: choose the least restrictive combination that still meets your EMI needs, then confirm that the system cools and sounds as expected under normal use. For more info, read the blog: How EMC Filter Placement Choked a Server Fan (And What Fixed It)

SANYO DENKI has been a trusted provider of cooling solutions for various industries, with fans being a crucial component in many advanced devices. Contact us for a quote, or to discuss your device's customization requirements.

Our experienced application engineers and field engineers will provide support on the customization or any other technical support for your equipment. Contact our representatives or distributors to start discussing your next project.

Contact Us